Search This Blog

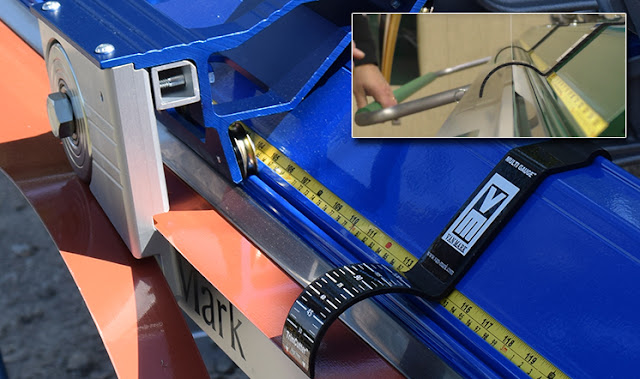

We are manufacturers of portable bending brakes, saw tables, slitters and gutter hood roll forming tools for the construction trades. In business for over 50 years, we have made a name in the industry by providing the strongest portable bending brakes found anywhere in the world.

Posts

Showing posts from 2017

Van Mark’s Knowledge Base: Our Technical Department

- Get link

- Other Apps

New career opportunity for a Machinist interested in working with an established family business!

- Get link

- Other Apps